EUROTEC Connections | MAGNUS L Connector

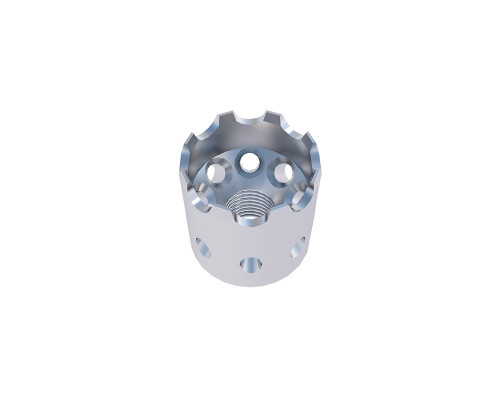

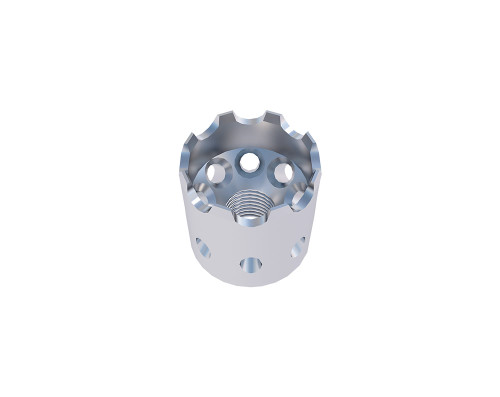

The MAGNUS L Connector is a concealed connections aluminium/timber connector designed for main/secondary beam joints in timber structures. It is suitable for use in service class 1 and 2, providing protection from direct weathering. This connector is ideal for creating node joints in timber-frame construction, allowing for prefabrication and minimizing assembly times on the construction site.

Product Uses

The MAGNUS L Connector is used to create node joints in timber-frame construction, offering high verified load values and the ability to statically load joints in five directions. It can be installed both visibly (for shadow-groove connections) and hidden (milled in), providing flexibility in design and application.

Technical Data

The connector consists of two separate components, along with wood construction screws and fixing screws. The two parts are attached to the respective structural members using the wood construction screws and then slotted into one another without the need for force. The components are braced against each other using fixing screws, ensuring prevention against accidental loosening. The installation process can be carried out using the milling and assembly jig for both visible and hidden installations.

Installation Instructions - Hidden (Milled-in) Main/Secondary Beam Joints

- Adjust the end stop of the milling and assembly jig to the desired size of the Magnus hook connector, apply and screw on the milling and assembly jig, and create a routed slot with the corresponding groove-milling cutter.

- Insert the Magnus into the routed slot and fasten it in place using the supplied system screws.

- Place the milling and assembly jig in the same position as before on the component that is to be connected, and screw on the second part of the Magnus hook connector.

- Pre-assembly is now complete, and the component being connected is hooked in place.

- Insert the fixing screws into the Magnus, pulling the Magnus hook connector together and ensuring correct positioning of the node joint.

This installation method demonstrates hidden installation, where there is no need to mill out a slot, and the milling and assembly jig is used only as an assembly jig.