Craftsman Hardware | Saw Blade Tooth Configuration

You need a high tooth count to obtain high quality results? Sometimes. But tooth configuration is equally, if not more important. Tooth count will allow the tooth configuration to do what it is required to do, not quicker, but simply, at higher intervals. A higher tooth count does not always mean higher quality or cuts, or even faster. Again, feedrate or cut rate can depend on a number of factors including gullet size.

In general though, when you require a high quality cut with smooth finishes, choosing the correct tooth configuration and tooth count should provide optimal results. The width of the tooth, is called the kerf, and this is the cutting width of the saw blade ultimately. It is important when choosing the right blade, to think about whether a higher tooth count is required, or if a thicker blade will suffice for the job.

It is often mistaken that the saw marks left behind, is from a low tooth count, when it can also be small amounts of movement in the saw blade. Sometimes, even both. The tooth configuration however, is not always the finish of the face surface on the cut, but, how clean a cut edge or groove is left after the cut.

The basic ATB is a versatile grind that has a bevel from the top, outer part of the tooth pitched down toward the opposite of the blade. The bevel sequence alternates from one tooth pitched from the left to one pitched from the right. This sequence continues around the whole blade. The angle of the bevel on the tooth is typically between 10 and 20 degrees. A bevel at 20 degrees will make a cleaner cut than one at 10 degrees. However, it cuts slower and produces more heat through friction. Typically good for cross cuts.

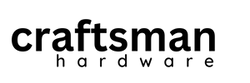

The ATBR is the last ATB-style saw blade. It is also known as ATAFR, but it’s more commonly called ATBR. It usually has a repeating pattern of 5 teeth. The first 4 teeth are ATB style, and the 5th tooth is a flat-top raker. The flat top raker tooth leaves behind a flat surface after it cuts. It has a large gullet between each 5 tooth sequence to remove sawdust efficiently. The ATBR is optimized for crosscuts.

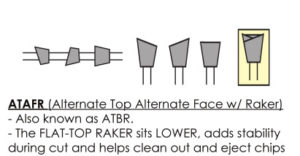

FTG saw blades are designed to rip wood with the grain. They are optimized to remove chips of material and sawdust from the teeth quickly and efficiently. The FTG blade makes fast, efficient cuts, and is durable and long-lasting. One downside to consider is that it will chip and cause considerable tearout on almost all cuts. Keep that in mind when using it on materials and woods where appearance is important. The FTG is also the only tooth design that leaves a perfectly flat bottom when grinding.

The TCG design combines a trapezoid-shaped leading tooth followed by a flat raker tooth that sits slightly lower. This pattern continues around the whole blade. TCG blades combine balanced cutting force with low tooth drag and free chip flow. These characteristics make the TCG one of the more durable blades. The TCG tooth style produces very little chip out and tearout when cutting brittle materials. This makes it a good choice for cutting chipboard (OSB), ferrous and non-ferrous metals, plastics, MDF, laminates, and very hardwoods.